To help you choose the ideal video wall for your control room, it's essential to thoroughly analyze the display solutions currently available on the market. This article compares the three main technologies dominating the industry, guiding you toward the most informed decision:

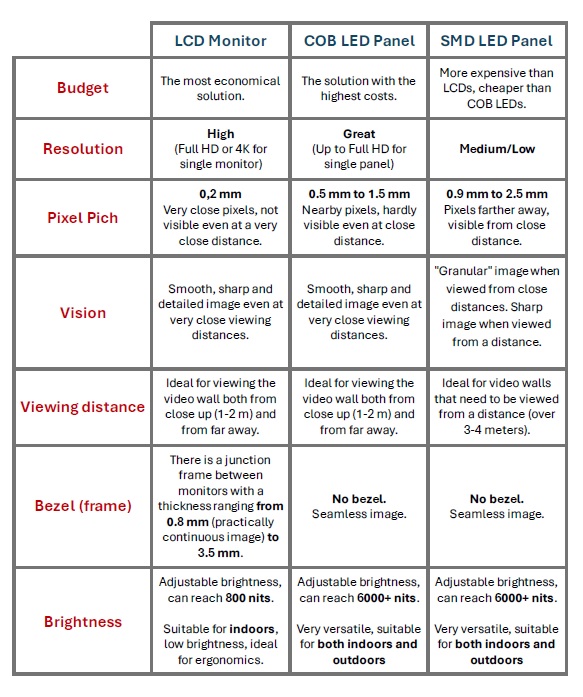

Before diving into a detailed analysis of the pros and cons, and to help you decide on a control room video wall, let's explore the key features of the three main technologies. We'll provide a basic overview of LCD monitors, SMD LED panels, and COB LED panels, laying the foundation for a better understanding of their advantages and disadvantages in control rooms.

LCD technology uses liquid crystals to form images. These crystals do not emit light themselves, but act as a sort of filter that blocks or allows light from a rear light source, called a backlight, to pass through. In modern displays, this backlight is almost always LED.

How it works: An LCD monitor is composed of millions of pixels printed directly on the panel, each made up of red, green, and blue subpixels. An electrical signal rotates the liquid crystals, controlling the amount of light passing through each pixel to create the desired color and brightness.

Resolution: The pixels in an LCD monitor are microscopic and are printed on the surface of the panel at a fixed, extremely high density. They are so small and closely spaced that, unless you use a magnifying glass, you can never distinguish individual pixels. LCDs are fixed-resolution displays, meaning the number of pixels is predetermined.

Unlike LCDs, SMD LEDs are self-emissive displays, meaning the pixels themselves emit light.

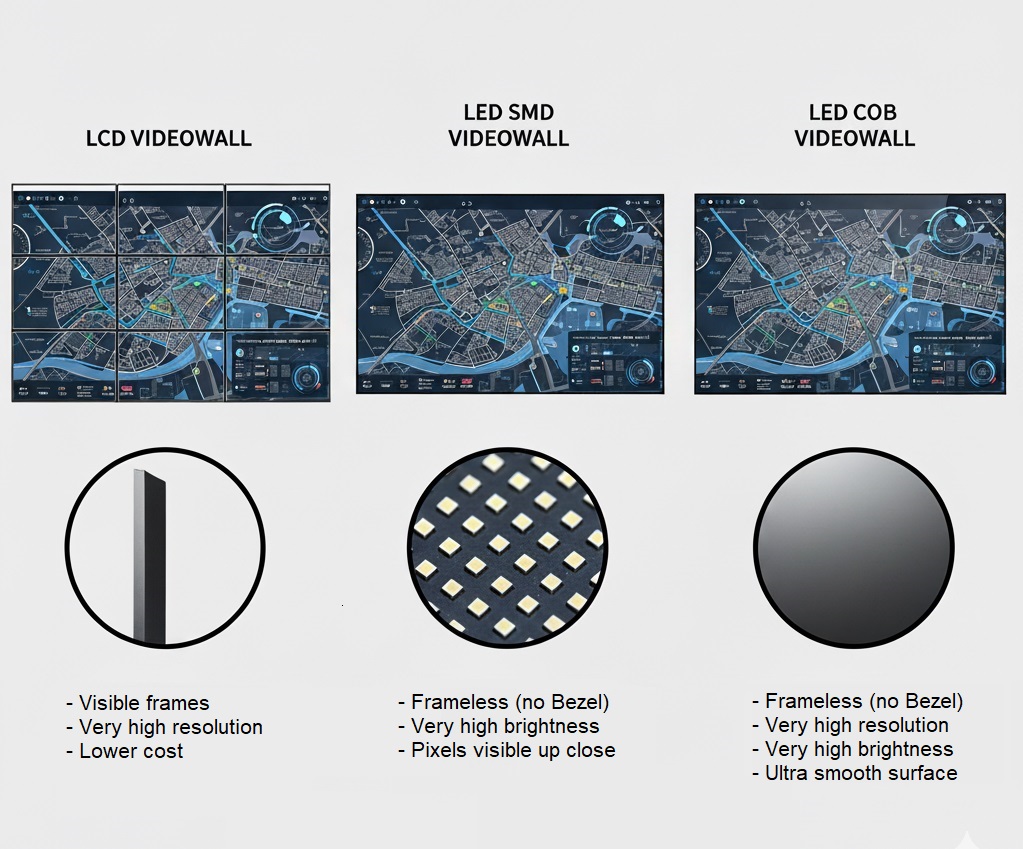

How it works: Instead of having three separate LEDs for each pixel, in SMD technology, these three small LEDs (red, green, and blue) are encapsulated in a single, compact black "package." These packages are then soldered directly to the surface of a printed circuit board (PCB) to create a single module. SMD modules have no bezel and can be tiled to create a video wall of any size and shape without visual interruptions.

Resolution: The distance between pixels in an SMD LED depends on the physical dimensions of the SMD module. For an SMD LED video wall, the distance between the packages is a limiting factor. If you get too close, your eyes will perceive the gap between each SMD package, making the image appear "grainy" or "blurry". Due to the greater distance between its "pixels" (the SMD packages), an SMD LED video wall, at the same physical size as an LCD monitor, will always have a lower visual resolution and will display less detail when viewed up close.

COB technology is the latest and most advanced evolution of LED video walls. It retains the principle of self-emissive LEDs, but with a radically different structure.

How it works: Bare LEDs (without protective encapsulation) are mounted and soldered directly onto the printed circuit board. The entire surface of the module is then coated with a layer of epoxy resin or polymer material. This protective layer seals the pixels, making the display surface completely smooth and resistant to shock, dust, and moisture.

Resolution: The lack of encapsulation allows the chips to be positioned much closer together. The main advantage is the ability to achieve a narrow pixel pitch compared to other types of LEDs, which translates into extremely high resolution and very short viewing distances. The smooth surface improves contrast and reduces reflections.

High Resolution and Low Cost: A more economical solution than LED panels but that offers the highest image resolution for close-up viewing.

Main Disadvantages

Visible Bezels: Although minimized, the frames between LCD panels are still present and can interrupt the overall image, compromising the visual fluidity of maps or panoramic videos.

Excellent Resolution and Seamless Image: Very small pixel pitch compared to other LED types, high-resolution and seamless images, minimal viewing distance. The absence of bezels creates a single visual canvas.

Main Disadvantages

High Cost: This is the most expensive option in terms of initial investment.

High brightness and Seamless Image: Their high brightness makes them suitable even for very bright environments or for installations requiring a strong visual impact. The absence of frames creates a single visual canvas.

Main Disadvantages

Pixelated image effect, low resolution: Pixels are farther apart than other solutions, resulting in a "dot" effect and a "grainy" image when viewed up close.

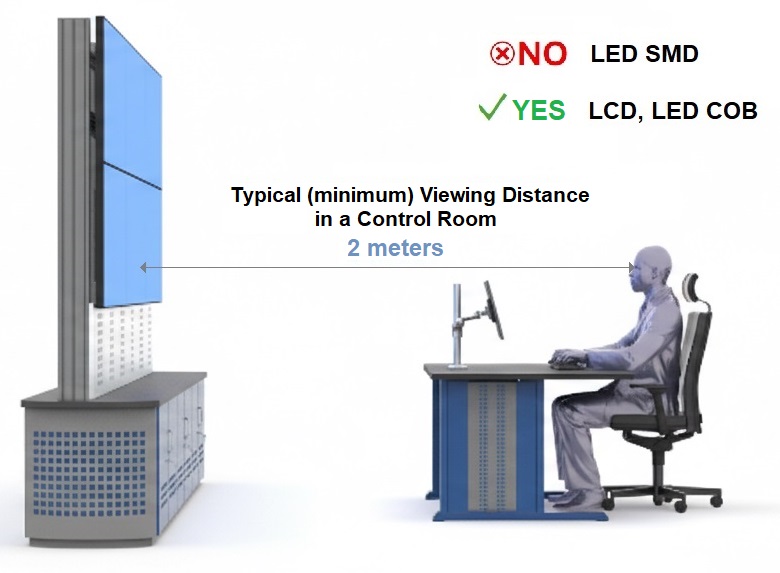

The viewing distance in a control room is a crucial factor for ergonomics and data readability. On average, operators position themselves 2 to 5 meters from the video wall.

This distance is the result of careful ergonomic and functional design that considers several factors.

The main factor to consider, beyond ergonomics, is the type of content displayed on the video wall.

Viewing distance requires a precise choice of pixel pitch.

It is essential that the video wall pixel pitch is chosen based on the minimum viewing distance. Considering a viewing distance of 2 meters, it is essential to choose a video wall with a maximum pixel pitch of P0.9 mm to ensure a sharp, eye-friendly, and not "pixelated" image.

Navigating the video wall options for a control room requires careful consideration, balancing performance, ergonomics, and budget. After analyzing the main technologies, we can outline clear decision-making paths for your control room.

Although SMD LED panels are versatile in many contexts, we do not recommend them for the critical environment of a control room, where close-up viewing and ergonomics are essential. Their physical limitations, related to their medium pixel pitch and their particular structure with visible LEDs, can compromise image clarity at close range, causing a "grainy" effect that fatigues operators and reduces monitoring effectiveness.

Both LCD monitors and COB LED panels emerge as excellent choices for a control room video wall. Both technologies guarantee:

Ultra-high Resolution: Impeccable detail for reading critical data.

Adjustable Brightness: Essential for visual comfort and ergonomics.

Durability and Reliability: Crucial for 24/7 operation environments.

The final decision between these two options comes down to three main factors:

Visual Impact and Image Continuity: A COB LED video wall offers an unparalleled viewing experience. With a completely seamless image and an ultra-smooth surface, it creates a unified, aesthetically striking screen. If your goal is a futuristic aesthetic, a perfectly uninterrupted view, and maximum durability, COB LED is the right choice.

Cost: This aesthetic and technological superiority of COB is reflected in a significantly higher cost, often three or more times that of an equivalent LCD solution. Opting for an LCD video wall, on the other hand, means getting high visual performance and proven technology at a significantly lower cost. Furthermore, considering that modern bezels are almost imperceptible, a minimal interruption in visual continuity can be accepted in exchange for significant savings while still maintaining high standards of resolution and reliability.

Ultimately, for your next control room: consider the trade-off between the aesthetic and functional perfection of COB LEDs and the excellent value offered by LCD monitors. Both solutions will ensure operational efficiency, but with different impacts on your budget and overall visual impact.